Within the bustling environment of a specialty coffee roastery, every hour is filled with a flurry of activities beyond just roasting coffee. While roasting may be the initial thought, the reality encompasses much more, with significant emphasis on the safe and effective storage and transportation of roasted coffee within the roastery. These processes are crucial for the thriving of a roasting enterprise, necessitating adherence to best practices to maintain the coffee’s quality.

To delve deeper into the strategies for optimizing storage and transportation of roasted coffee, I engaged in a conversation with Roberto Pedini, an Expert Process Manager at IMF Roasters. Continue reading to uncover his valuable insights on preserving the excellence of roasted coffee.

How to safely and efficiently store and transport roasted coffee

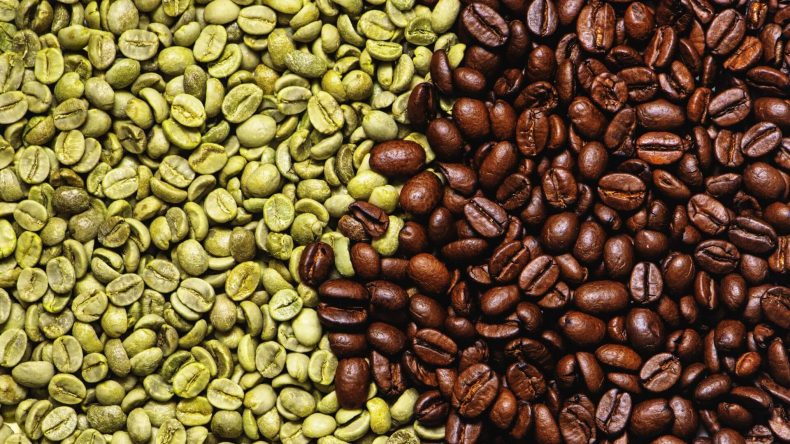

Preserving the freshness and quality of unroasted, or “green,” coffee beans is crucial before the roasting process begins. Proper storage conditions for green coffee are essential to maintain its inherent qualities, ensuring that, once roasted, the coffee offers a full spectrum of flavors for consumers to enjoy.

Typically, green coffee retains its freshness from six months to a year after being harvested. In contrast, roasted coffee is far more perishable, with its freshness declining within just a few weeks. This difference in stability stems from the roasting process itself, where high temperatures trigger numerous chemical reactions within the green coffee. These reactions transform the beans’ cell structure, unlocking the flavors and aromas that define the coffee’s character.

Throughout roasting, gases such as carbon dioxide (CO2) are generated inside the coffee beans. While a portion of CO2 and water vapor escapes during the roasting, much remains trapped within the beans due to their porous nature, which readily absorbs gases.

Eliminating gases & ensuring freshness

In the weeks following roasting, coffee beans undergo a natural process of releasing carbon dioxide (CO2), known as maturation and degassing. This phase is critical for the beans’ development. Notably, grinding the beans accelerates this release, expelling 60% to 70% of their CO2, which signals a rapid decrease in freshness. Consequently, the presence of CO2 within coffee serves as a tangible indicator of its freshness. In essence, coffee without CO2 cannot be deemed fresh.

Furthermore, CO2 plays a pivotal role in safeguarding roasted coffee against oxidation, a culprit in making coffee stale and diminishing its flavor quality.

Roberto emphasizes the importance of proper storage for roasted coffee to maintain its aromatic and flavor integrity and to avert oxidation.

Interestingly, there’s a phenomenon where coffee can be “too fresh.” Grinding and brewing coffee immediately after roasting, when it’s still rich in CO2, can obstruct the extraction process, leading to a brew that’s often astringent and sour.

Therefore, coffee experts often advise waiting a few days post-roasting before grinding and brewing the coffee. The optimal waiting period varies, influenced by factors like the coffee’s variety or species, its processing technique, the density of the beans, and the roast profile.

Enhancing food safety standards

Globally, the specifics of food safety standards may differ for coffee roasters. Yet, irrespective of their location, it’s imperative for them to maintain the purity of both their roasted and unroasted coffee beans.

While the roasting phase effectively eliminates harmful pathogens and microorganisms, rendering it a critical “kill step” there remains a risk of contamination post-roasting.

Improper storage environments and inadequate facilities can lead to infestations of pests and insects in roasted coffee beans. Likewise, under conditions of warmth and humidity, there’s a heightened risk of fungal and mold growth in roasted coffee, underscoring the need for meticulous storage practices.

So, what’s the secret to storing and transporting roasted coffee?

When selecting a storage solution for roasted coffee, numerous roasters favor silos due to their specialized design, which safeguards the coffee beans against oxygen, moisture, and various environmental threats.

Roberto mentions, “IMF offers an array of silos, varying in size, shape, and design, adaptable for outdoor installation should space be constrained within a roastery.”

In addition to preserving coffee in ideal conditions, it’s crucial for roasters to manage the storage and transportation of roasted coffee beans within their premises efficiently and safely.

To facilitate the transport of green coffee beans to the roasting machines, many roasters employ pneumatic conveyors, conveyor belts, or trolleys, enhancing the efficiency of moving large quantities of green coffee and mitigating the risk of injuries associated with lifting heavy weights.

Roberto emphasizes, “Ensuring the protection of coffee during transportation on a pneumatic conveyor or conveyor belt is vital to prevent bean damage and quality deterioration. IMF’s solutions are grounded in specific technologies and designs for secure coffee handling.“

He further advises, “The transportation of roasted coffee beans should be conducted gently and slowly, paying careful attention to controlling speed and pressure. Pneumatic conveyors offer the most adaptable and hygienic option, whereas mechanical conveyors are preferred for shorter distances.” For roasters globally, adherence to food safety standards and regulations may differ. Regardless of their location, it’s imperative for all roasters to ensure their roasted (and green) coffee is devoid of contaminants.

Though the roasting process eliminates many harmful pathogens and microorganisms, posing as a “kill step” there remains a risk of contamination for roasted coffee.

Lack of proper storage facilities and conditions can lead to pest and insect infestation or nesting in roasted coffee beans. Similarly, in conditions of warmth and humidity, fungi and mold growth is a possibility in roasted coffee.

Strategies for preserving freshness after roasting

In a manner akin to the transportation of green coffee beans, numerous roasters adopt methods such as pneumatic conveyors, conveyor belts, or trolleys for the seamless transfer of roasted coffee beans from the roasting machine to various storage solutions. Optimizing the layout of the roasting area for efficiency and ergonomics significantly enhances this transition process.

Ensuring the roasted coffee is stored in containers that safeguard against oxygen, humidity, and other external elements is critical. This necessity leads many roasters to opt for silos as the preferred storage solution for roasted coffee.

Equally important is the requirement for storage systems to facilitate the beans’ proper maturation and degassing process. For example, Roberto highlights that the silos designed by IMF for roasted coffee come equipped with specialized degassing valves, enabling the consistent release of CO2.

Essential tools for coffee roasting success

Regardless of the storage and transport methods chosen, it’s crucial for roasters to invest in top-notch equipment.

“Professional and superior quality equipment, tailored for the meticulous handling of roasted coffee during storage and transport, is indispensable” Roberto asserts.

Utilizing silos is among the most effective strategies for maintaining the freshness and integrity of roasted coffee, significantly reducing the risk of contamination.

“Constructed from steel, IMF’s silos come equipped with shock absorbers to drastically lower the chances of bean damage during the loading process” Roberto shares.

This aspect is particularly vital as damaged or broken beans can significantly diminish the quality of the coffee, adversely affecting the consumer’s enjoyment as well.

Yet, perhaps the most critical equipment in any roastery is the roaster itself. The absence of a high-efficiency, professional-grade machine means roasters are unable to consistently achieve superior roast profiles.

Roberto highlights that certain roasters, including those from IMF, incorporate heat retention and recirculation technologies. These innovations not only enhance the consistency of roast profiles but also cut down on energy use, leading to cost savings.

Unlocking the rewards of expertly managed roasted coffee inventories

First and foremost, adherence to food safety regulations is a fundamental requirement for any coffee roaster, ensuring their products are free from any contaminants and debris. Beyond this fundamental obligation, it is crucial for roasters to preserve the quality and freshness of their coffee. Given the substantial investments many specialty roasters make in acquiring premium green coffee, it is vital they deliver an end product that encapsulates the full spectrum of flavors and aromas, fostering greater consumer trust and brand loyalty.

Additionally, optimizing efficiency and reducing waste are essential considerations. The time roastery employees spend moving coffee within warehouses can be significantly reduced through investments in technologies such as conveyor systems, thereby enhancing operational efficiency and potentially elevating profit margins.

Moreover, integrating systems like silos, dosers, and automated packaging lines can notably diminish waste, cut costs, and optimize space utilization within the roastery.

Roberto highlights the role of IMF conveyor systems in streamlining the transfer of roasted coffee to packaging lines, emphasizing the critical importance of storage and transportation in maintaining the high quality of roasted coffee. Due to the volatile nature of roasted coffee, proper storage and transportation solutions are paramount to minimize the degradation of its freshness and quality.

Investing in advanced storage and transportation technologies, such as those featuring heat retention and recirculation, is advised. According to Roberto, these technologies not only ensure the consistency of roast profiles but also contribute to lower energy consumption and reduced operational costs, demonstrating the comprehensive benefits of adopting such innovations for maintaining coffee excellence.

FAQs: