The pursuit of sustainability has become a critical objective for coffee roasting in recent times. This encompasses not only the ethical and traceable sourcing of coffee beans but also the environmental footprint of the roasting process.

While much of the coffee industry’s sustainability initiatives have traditionally centered on production and retail levels, the roasting segment is equally critical. Progressive roasters are now actively seeking ways to diminish their emissions and operational costs by investing in advanced, eco-friendly roasting technologies.

To gain further insights into these developments, I engaged with Lorenzo Mosca, a Production Engineer at roaster manufacturer IMF, and Will Notaras, the Australian Sales Manager for IMF. The following discussion delves into strategies for reducing emissions during coffee roasting and underscores the significance of such efforts.

Addressing Sustainability Challenges in Coffee Roasting

Sustainability concerns within the coffee roasting sector mirror those across the entire coffee supply chain, with significant emphasis on environmental impact.

The roasting process is not without its drawbacks, chiefly the generation of smoke, particulate matter, and an array of emissions including carbon dioxide, carbon monoxide, and nitrous oxide. These byproducts, particularly in large volumes, pose health risks to humans and contribute to environmental degradation.

Lorenzo Mosca sheds light on the issue: “The gases and dust released during roasting, if not properly managed, can be detrimental to both the health of coffee professionals who work in close quarters with roasting equipment and the broader environment due to their contribution to global warming.”

The Imperative for Emissions Reduction in Coffee Roasting

As the tangible effects of climate change intensify, the onus is on coffee roasters to seek avenues to curtail their carbon footprint. Research indicates that global warming poses a dire threat to coffee cultivation, with projections suggesting that by 2050, up to half of the land currently suitable for coffee growing could diminish in both size and viability.

Will Notaras emphasizes the dual benefits of emissions reduction: “Lowering emissions not only benefits the environment by reducing your carbon footprint but can also lead to decreased gas usage and, consequently, lower energy costs.”

The current energy predicament, characterized by soaring gas and electricity rates, presents a formidable challenge for coffee shops and roasting worldwide. A shift toward more energy-efficient and sustainable machinery stands as a strategic response to manage and reduce these operational expenses.

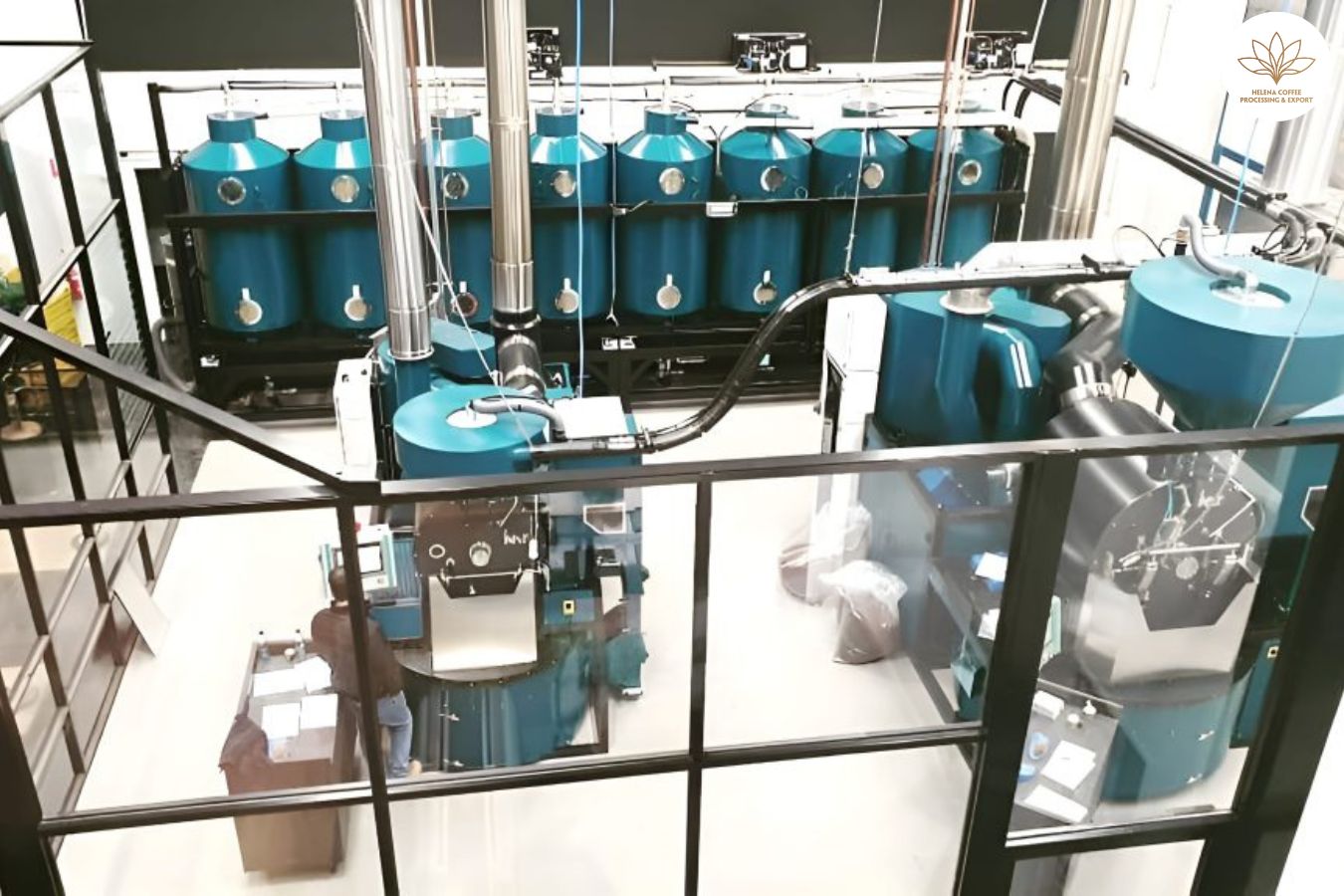

Modern roasting technologies, such as those incorporating heat recirculation systems, exemplify such advancements. Lorenzo Mosca from IMF elaborates on their commitment to innovation: “Our research has yielded cutting-edge sustainable solutions like the heat recirculation system, which repurposes clean hot air through a dual-purpose heating chamber.”

Will delineates the operation of this system: “It utilizes a singular burner both to neutralize emissions and to generate the roasting heat, thus achieving lower emissions and decreased gas usage.”

Lorenzo adds, “This innovation not only cuts down on energy use in the roasting cycle but also simultaneously reduces emissions, yielding savings on both energy and production fronts.”

The increasing consumer demand for sustainable practices also plays a crucial role for roasters striving to stay competitive. Lorenzo notes: “Utilizing eco-friendlier machinery signifies to customers a commitment to environmental stewardship, a value that resonates profoundly with the younger demographics.”

Indeed, studies have revealed that Gen Z consumers are prepared to spend more on sustainable products, including coffee, and alongside Millennials, they are more inclined to weigh social and environmental considerations in their buying choices.

Lorenzo concludes, “Investing in efficient, greener machines is tantamount to adopting more sustainable business practices, an investment that pays off not just in cost savings, but in aligning with the ethical expectations of a new generation of consumers.”

Strategies for Emission Reduction in Coffee Roasting

Roasters have at their disposal a variety of strategies to decrease emissions, with one of the most impactful being the upgrade to a sustainably designed machine.

Will Notaras points out an inefficiency in older equipment: “Traditional roasters often rely on a primary burner for roasting and an auxiliary afterburner for emission control, but this afterburner can significantly increase greenhouse gas emissions due to its high gas and temperature requirements.”

He contrasts this with more innovative designs: “IMF’s roasters, for example, utilize a single burner for both roasting and emissions reduction, which results in lower gas usage and fewer emissions.”

When considering new equipment, Will advises looking for specific features: “Technologies like heat recirculation are critical for minimizing gas consumption and emissions. Additionally, our patented vortex and equalizer system helps achieve more consistent roasting profiles.”

For smaller operations, the initial investment in a new roasting machine can be daunting, and the transition might entail significant adjustments to their roasting processes.

Lorenzo Mosca offers a solution for those not ready to purchase a new roaster: “It’s possible to retrofit current machines with more efficient components to lower emissions, including various gas abatement systems such as thermal or catalytic oxidizers.”

These systems can alter the chemical makeup of emissions, effectively reducing harmful outputs and bringing operations in line with environmental regulations while also cutting energy use.

Lorenzo also suggests modifying roasting practices: “Traditional machines often yield higher emissions at elevated temperatures or with darker roasts. To cut emissions, roasters might experiment with lower temperatures, shorter roasting times, or medium roast profiles.”

He further emphasizes the importance of proper ventilation systems in enhancing sustainability and efficiency: “Optimizing airflow management through more advanced ventilation can curtail emissions, particularly during the latter stages of roasting.”

Regular maintenance is another key point Lorenzo stresses: “Keeping chimneys and ductwork clean of oils and particulate matter is crucial for emission control.”

In summary, roasters intent on diminishing their environmental impact should thoroughly assess their current setup for any inefficiencies or outdated equipment that could be improved or replaced.

The inexorable shift towards sustainability in the coffee industry is set to intensify in the forthcoming years, placing an ever-increasing emphasis on the adoption of energy-efficient roasting machines. This transition, while essential for emission reduction, also presents a compelling economic benefit: modern, energy-efficient roasters can significantly lower operational costs—a boon for businesses navigating the financial challenges of the current era.

FAQS: