Dry Processed Coffee: Separating the coffee cherry’s fruit body and peel from the coffee beans is a critical element of coffee growing. How coffee is processed has a significant impact on the finished cup, and roasters and baristas are increasingly focusing on coffee processing to characterize the coffee.

Dry processing is one of the simplest and oldest methods of processing coffee in the history of the coffee industry, often applied in robusta coffee processing. Let’s go through dry processing methods with Helena Coffee Vietnam.

The objective of farmer-owned coffee processing is to remove the bean from the coffee cherry while retaining the coffee’s profitability. Even if the coffee was harvested ripe and the harvest went well, poor coffee processing might result in faults that detract from the coffee’s value.

Since dry processing requires less time, money, and natural resources than other methods, selecting dry processing can be a critical decision for a coffee grower or producer.

How Is Coffee Processed?

Because coffee seeds (also known as “beans”) develop within the fruit of trees, there are many procedures needed before we get to the actual coffee seed that we roast, ground, brew, and consume.

After the cherries are plucked from the coffee plants, they must be processed to separate the peel and pulp from the seed.

Processing refers to the methods used to turn a picked cherry coffee cherries into a green coffee bean that is ready for roasting. It is one of many steps that coffee must go through before it is brewed.

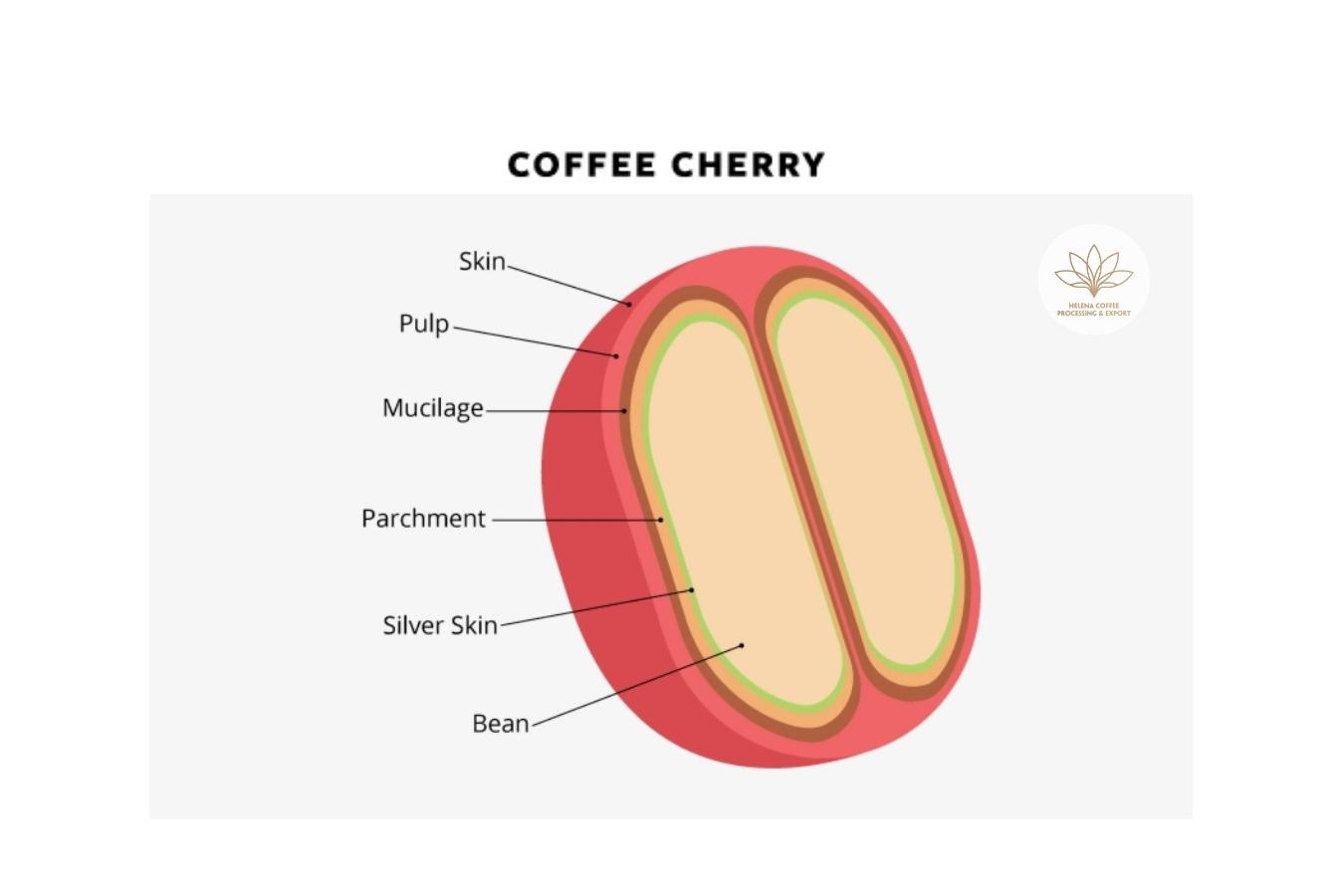

It includes the steps used to remove the three layers that surround the coffee bean, the cherries, the mucous membrane, and the parchment, as well as how the beans are dried. There are three main ways that coffee is prepared, and each creates its own distinct characteristics. They come in dry, wet and semi-washed forms.

Basics Of Dry Processing – What Is Dry Processed Coffee Beans?

- Definition:

Dry processing, also known as a natural process, unwashed, or natural sundried, includes drying coffee cherries in the sun on patios or raised beds. To keep the cherries from rotting, they are raked and rotated throughout the day, then covered at night or during rainstorms.

After the coffee cherries have been picked from the trees, they are spread out in thin layers to dry in the sun. Depending on the farm or region, the drying stations can vary; some use brick patios, while others use unique raised beds (=tables) that allow air to flow around the cherries, resulting in more even drying.

The cherries are rotated frequently to prevent mould, fermentation, and rotting. After the cherries have dried sufficiently, the peel and dried fruit meat are mechanically removed, and the green coffee is kept and “rested” before being exported.

- Production time:

This is the more conventional way of preparing coffee, which generally takes 3-6 weeks.

- Popular area:

The natural process is prevalent in locations with no access to water, such as Ethiopia and some sections of Brazil and Vietnam’s Central Highland provinces. It works best in low humidity and sporadic rain, such as in Ethiopia and Yemen.

In the places where it is utilized, the procedure is primarily traditional, and there hasn’t been much progress in natural processing in recent years.

Detailed Procedure Of Dried Processing Coffee

Primary method: Coffee is dried in various ways: some farmers use high beds, some dry coffee on the pitch, while others use a combination of high beds and mechanical dryers. Regardless of these differences, the natural drying process does not necessitate complicated equipment.

Primary machines of dry processed coffee: The coffee is laid on raised drying beds that allow air to circulate through the fruit. The beds use metal screens or metal bands that support a nylon woven cloth (preferable). Sometimes locally woven grass mats are used.

Natural processing is one of the oldest procedures, although it has only recently made its way into the speciality coffee market. Ethiopia, Yemen, Brazil, and Costa Rica are the most popular places to get naturally processed coffee, although growers all around the world are experimenting with it.

Biotransformation process in dry process coffee: The outer layer and connected pulp (exocarp, mesocarp) adhere to the parchment covering as the cherry dries (endocarp) lie a layer of mucilage that is destroyed by fermentation in the wet phase. The silverskin frequently clings to the bean.

The pulper peels off the fruit skin in wet-process (WP), and the remaining fruit is fermented and rinsed off.

On the other hand, the coffee seed dries encapsulated by the thicker layer of fruit skin in DP. The fruited flavours of a DP coffee are likely incorporated into the drying seed by active water transfer and ionic interaction with chemicals in the fruit peel.

Characteristics Of Drying Process Coffee

Feature #1: Save water

In areas where water is limited, the natural method is often employed. The wet-process technique uses a lot of water to sort the coffee cherries and prepare the beans. At the same time, another approach is utilized in locations where water shortage is a significant issue. Coffee with “fruitier” characteristics results from this dry procedure.

Some opponents argue that washed coffee is preferable to natural coffee because the wet procedure removes any “outside contaminants” from the coffee’s taste.

Feature #2: Easy to do, low cost

Because of its simplicity and the fact that the fruit remains whole and undisturbed, it’s commonly referred to as “natural coffee.” It’s similar to drying grapes into raisins.

The dry process technique is the default for producing inexpensive commodity-grade coffee in places with a suitable environment for drying the fruit and seed since it involves low investment.

Feature #3: Difficult to control, easily damaged

In humid or damp climates, however, it is a failure. The fruit declines, rots, or moulds if the drying process is not completed quickly enough.

Coffee that has been dry-processed may also be quite uneven. The dry process requires more manual effort than the wet process if you want a cleanly fruited, sweet, powerful cup.

The most meticulous cherry pickers may remove green unripe or semi-ripe coffee off the branch while picking red, ripe cherries. If they aren’t removed during the first few days of drying, the green acquires a brown colour that’s difficult to differentiate from ripe fruit.

There are arid zones where the coffee begins to dry while still on the tree. Brazil’s wet and dry seasons are highly different, and during the dry seasons, when coffee is picked, the heat is severe enough to dry the coffee fruit while it is still on the branch. In Latin America, they are known as “pasas,” or raisins, and they have a leathery feel.

Feature #4: Easily affected by weather

The drying time may be affected by various conditions; for example, wet or gloomy days would make the process take considerably longer. Beans that take longer to dry may ferment more, resulting in different taste notes. This is why the natural approach to processing is so appealing! It may provide distinct findings since it is an inexact science.

Feature #5: Takes a lot of labour

Workers using long rakes distribute and flip the beans and fruits throughout the day as they dry in the sun to ensure uniformity in the drying. The cherries are covered at night or when it rains. On bright mornings, the covering is removed to let ventilation and hot sunshine do their job.

Feature #6: Easily destroyed by mould

In hot and humid conditions, mould cells proliferate and thrive in coffee beans with abundant nutrients. Therefore, Coffee mills will sometimes utilize mechanical dryers instead of sunshine to dry the coffee cherries.

This allows for more consistent outcomes as well as better taste control. It also eliminates losing product due to over-fermentation, mould, or other contaminants that cause “off-flavours.” When the moisture level of the coffee cherries reaches roughly 11%, they are ready to be dried in the sun or in a drier.

Flavour

Natural processed coffees are divisive among baristas in taste; some adore them, while others despise them. Regardless of the type or locale, the natural process imparts flavours such as fruitiness and sweetness to the coffee.

Blueberry, strawberry, tropical fruits, and honey are common taste notes in natural processed coffee, but there may also be wild, fermented flavors, and alcohol-like undertones.

Natural coffees are sometimes characterized as having red wine-like flavours compared to washed coffees. Natural processed coffees may be an excellent way for roasteries and baristas to show off what coffee can taste like and expand people’s minds. Still, they can also be off-putting to those who don’t enjoy fermented or wild tastes in their coffee.

Naturals have a higher concentration of fruit and fermented tastes because the bean has more opportunity to interact with the natural sugars in the cherry when enzymes break down the mucilage around the bean. If producers do not dry naturals correctly, rotating them frequently and eliminating overripens, unpleasant tastes will develop in the roasted coffee.

Processing Techniques

After harvest, wet-processed coffee is extracted from fruit skins, whereas dried-processed coffee is manufactured oppositely. The coffee fruit is plucked when fully mature and allowed to dry completely before peeling (peeling). While this peeling used to be done by hand with stone mortars and pestles, it is now done by machines that can be calibrated more precisely.

The first step in dry processing is to pay close attention to the harvesting stage, ensuring that you select it at the optimal moment — when it’s ripe. Another critical step is to categorize coffee according to its ripening stage. The taste of the finished dish might be severely harmed if the fruit is undercooked or overdone.

Fermentation

Fermentation takes place at every stage of the coffee production process, beginning with the picking of the beans. The sugar and acid inside the coffee fruit will be metabolized immediately by populations of yeast and bacteria present on the fruit surface (or that have entered the fruit due to mechanical impact during harvesting and transport).

Even though coffee is not held in a “fermentation tank” and is not subject to the same regulations as wet processing, it is nevertheless processed. However, many factors can influence the fermentation process when processed dry, including ambient temperature, sun exposure duration, shadow density, fruit density on exposed furrows, wobble–coffee rotation during drying, etc.

The entire drying process is mainly reliant on environmental conditions, such as sunshine, and can take one to three weeks. During this period, it’s crucial to scrape multiple times a day to ensure that the fruit layer dries uniformly and mould doesn’t grow.

You must plant coffee in heaps at night and cover the tarp to avoid night dew. The coffee fruit can be fermented by the enzyme system in the fruit itself if the coffee layer is irregularly spread or spread too thickly, making the coffee taste unpleasant afterwards.

Quality Control

After three to five days of exposure, the coffee will feel like rubber – due to the dehydrated fruit crust. At this point, the coffee can be arranged 5-6 inches thick to expand the space. And after about a week from the start, you will begin to evaluate & decide when to end the drying process.

When the crusts turn, dry, and almost turn black, the drying process ends close to the shell. Coffee beans that are not dry enough will be susceptible to degradation (mould) by bacteria and mould. Meanwhile, over-dried coffee becomes brittle and cracks during the grinding process (the coffee beans might also break along the way).

It is essential to dry the coffee to a humidity of less than 11% (or 12-10%). It is necessary to have a suitable temperature; Therefore, dry processing is usually carried out outdoors with an ambient temperature of about 29-31°C.

Finally, after reaching the required humidity, the coffee can be collected, packed, and stored in a dry and airy place until the buyer is ready to receive the goods.

What Is The Quality Of Natural Processed Coffee?

Specialty coffee manufacturers often stay away from dry processing. They know that temperature and humidity, unreliable and difficult to predict, will significantly impact the quality of coffee kernels.

As a result, dried processed coffee often comes from producers with little commitment to quality, places that lack the resources to invest in post-harvest infrastructure, or areas where water is scarce during the harvest period (especially Ethiopia, Indonesia, Yemen, and Brazil).

However, there are many reasons why dried coffee has become more popular. When scientifically applied and the fermentation process is controlled, the taste of natural processing will improve significantly.

It uses less water and energy. It also requires less infrastructure. In other words, dry processing is of good quality, environmentally friendly, and inexpensive – a preeminent trio if you have a suitable climate.

Market Demand

Natural coffees are said to be the first way of brewing coffee. If Yemen were the first country to cultivate coffee as a commercial commodity for commerce, the climate would be ideal for dry processing. Traditional dry-processing locations, such as Harar, are found in Ethiopia’s western regions.

Both older and younger coffee-growing areas of Brazil (Cerrado) have unique seasons best suited to the dry process method. If a farm can dry coffee from ripe cherry to hard, dried pod in 20 days, it’s undoubtedly a good candidate for dry processing.

In general, we will cup but not buy naturals from places where the coffee cannot be dried in the required length of time. Naturals from Central America are a fantastic example, but we’re constantly interested in learning about new locations and businesses that can do it correctly.

Several locations that did not previously produce dry-processed coffee have begun to do so in recent years. The spread is due to market demand since many purchasers find it easier to identify the flavours of dry processing coffees for themselves and their consumers.

There is, without a doubt, a question of personal preference, which is impacted by cultural biases. Although the distinction between clean fruit notes, winey fruit notes, and vinegar appears to be universal, there can be conflicts at the table.

The “ferment” of one person is the “fruited” of another. So there you have it. Many new purchasers, especially those from countries with a younger coffee tradition, are quick to exalt or condemn these fruit overtones.

The steadiness of the coffee over time is one aspect of nature that isn’t so dependent on human preference. Dry processing coffees that haven’t been appropriately rested or dried too slowly may fade.

A little fruit note detected in a new arrival of such a coffee may be excellent at the moment, but it may dissipate after many months. Unless you add sugar, what’s left may be flat, woody or earthy aromas that few find appealing.

Aside from the environment, a good dry processing coffee needs a lot of handwork and numerous picking iterations. Many locations just do not have enough workers, or labor is unaffordable in many cases. To clean the coffee of imperfections in Brazil, they must only utilize dry mill machinery: Even selective hand-picking is excessively labor-intensive and would push up coffee prices to unsustainable levels.

However, as the dry-process technique has regained popularity, several fantastic new coffees have emerged that have the consistency, homogeneity, and clean taste of wet-process coffees but with nuanced, layered fruit tastes not found in their counterparts.

The Difference Between Dry Process Coffee, Pulped Natural Process, Honey Processed Coffee, Wet Processed Coffee

The number of cherries left on the beans before drying is the main difference between Natural, Honey, and Washed coffee. Whole ripe pods, honey, and natural ingredients dry natural coffee. However, coffee is pre-processed using the Washed technique, which removes the peel and these chemicals.

As a result, Natural coffee has a richer taste. Cafe Honey has a thicker “Body” due to the use of ripe peels that have been pulverized throughout the drying process. Washed coffee has a little cleaner flavour.

“This is due to the sluggish transport of sugars from the ripe fruit to the coffee bean during the drying stage,” Helena Coffee experts explain.

FAQs:

- How many types of coffee processing methods are today?

- What is the Difference between pulped natural process, process natural processing, cherry dry processing, coffee dry processed in green coffee beans? Are they the same?

- How to use honey processed coffee in roasting coffee beans process?