Honey Processing Technique On Coffee: Honey processed, a combination of dry and wet processing methods, produces grain coffee beans yellow like honey. It is almost impossible to find a unified name for this processing method.

It is sometimes known by the trade name Semi-Dry Process, Semi-Washed, or Hybrid Process. And in each region where this technique is used, it has a different name: In Brazil (where it was first applied), it is called Pulped Natural. Learn about Honey Coffee Processing with Helena.

The most apparent benefit of honey processing versus dry processing is the improvement of the efficiency of the drying process, as well as the taste properties through fermentation. According to Cafeimports, this procedure, on the other hand, reduces more dangers in fermentation than wet processing.

Honey processing techniques

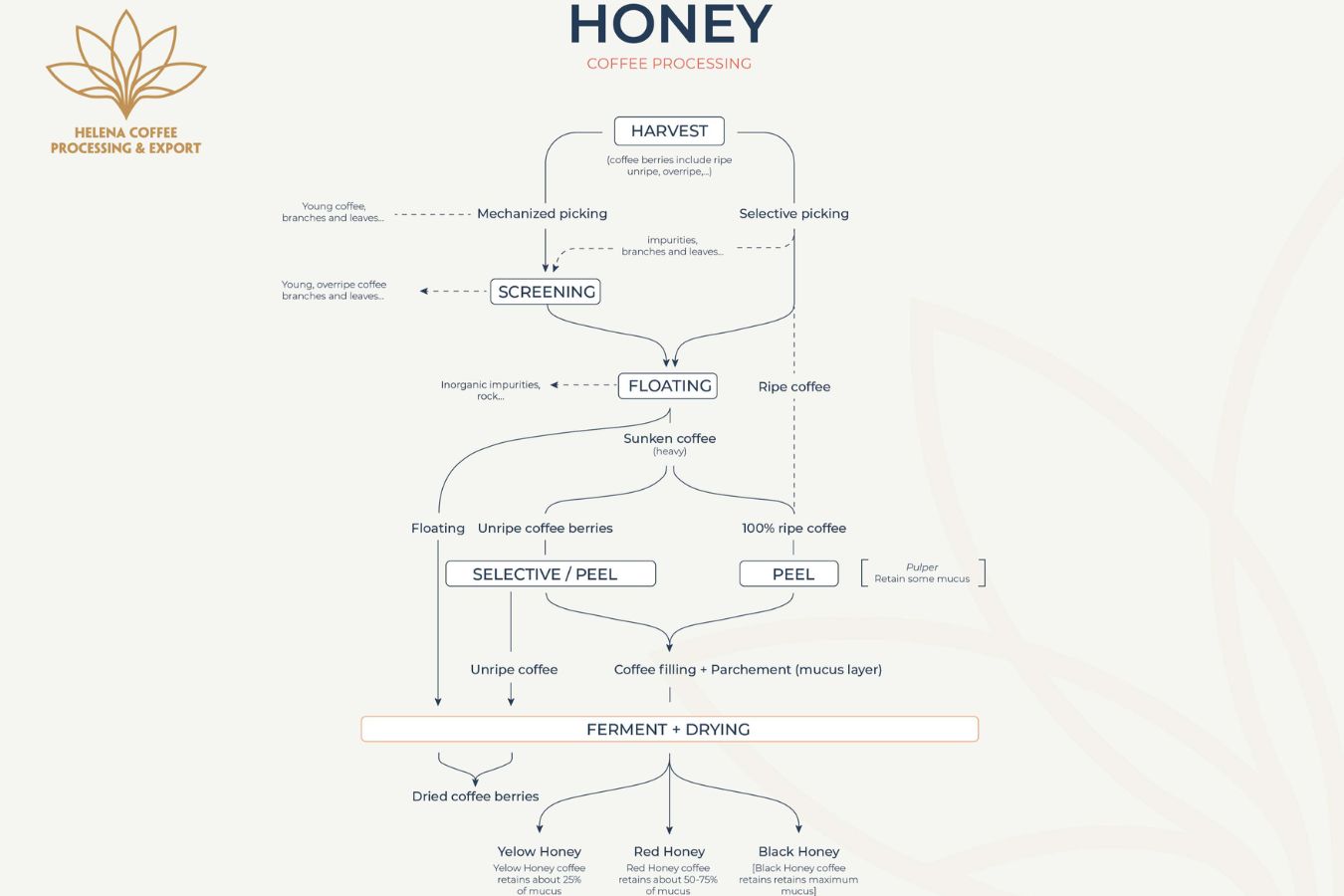

You can most easily come across three coffee processing techniques: natural, wet, and honey. Naturally processed coffee is dried before peeling and grinding. The damp coffee will be rubbed off the fruit peel to carry it away from fermentation, helping to decay the flesh layer (also known as mucus) before being dried.

Honey processing closes the gap between wet and natural drying. The coffee is peeled and then dried with the remaining layer of mucus. However, the above expression can be understood as a hybrid process. But it is just a simplified method of wet processing.

If in damp processing, after rubbing the fruit peel, the coffee is soaked in a fermentation tub for 24-36 hours, in the coffee honey method does not need to ferment, or only ferments short less than 12 hours to retain part of the mucus and transfer to the drying process to reduce the humidity to 10% to 12%.

The title“honey processed” leads many to assume that love is used to make coffee or coffee itself after brewing honey — but in fact, it’s not. This process is named from coffee beans’ sticky, honey-like sensation before being dried.

When the coffee bean is separated from the fruit crust, it will be covered with a mucous membrane, which, when dried, will continue to re-absorb moisture from the air and become sticky.

Distinguished from wet processing methods

The most distinctive part of the semi-wet processing method is that coffee still undergoes fermentation without using water. As is known, the main components of the mucous crust are water, carbohydrates (sugars), and organic substances such as pectin proteins. This layer of “fruit flesh” is very “mucous” is removed by mechanical engineering. However, they are very popular with bacteria.

The mucus will decompose due to the enzyme system secreted by microorganisms (and partly by the coffee beans’ enzyme system). In this way, the mucus layer will “disintegrate” entirely naturally, without much labor or mechanized machinery.

Although wet processing and honey processing both go through peeling – including mucus and outermost crust (collectively known as leprosy). But there are some differences in terminology in the process.

If the coffee is wet processed it will go through the peeling machine – commonly known as Demucilaged – and drain the maximum of the mucus it has; Meanwhile, the peeling machine for honey processing, called Pulper,retains some of the mucus that surrounds the seeds. This makes up the terms Pulp and Mucilage – the same mucous shells of coffee.

Since it does not require high mechanization, this method also consumes less water than traditional wet processing. More specifically, during wet processing, a large amount of water is used in fermentation tanks and the brewing process (wastewater discharge is a big problem with areas specializing in watery processing coffee).

On the other hand, wet processing methods are challenging to implement with water shortages. Meanwhile, semi-wet processing is an effective alternative when using less water. The discharge is also limited but still promotes the taste of coffee during fermentation – hence it is called Hybrid Process.

Honey processing began in the Middle Ages

In the early 1950s, the Campinas Institute of Agrocracy (IAC) in Brazil was the first to test semi-wet processing. Until the 1980s, a few farmers in southern Minas Gerais deployed on a commercial scale for the first time with positive quality impacts.

Sinhalese, a well-known industrial equipment manufacturer, created milling machines, set up pilot facilities in several Brazilian manufacturing zones and offered new goods to roasters at home and abroad, which led to widespread acceptance.

After a slow start in Brazil in the late 1980s, the new natural process began to be widely used by roasters in the 1990s. While the wet processing system was initially developed to deal with quality problems, on the other side, it is also used to exploit more distinctive flavors and qualities.

And so it is expanded from Brazil to other regions such as Central America, where called honey processing coffee and dried for a longer time with higher humidity, resulting in more decadent flavors.

After honey-processing coffee from Costa Rica won the Cup of Excellence in 2017 and second place in 2018, many roasters spread the word about the technique as a special method originating in Costa Rica.

In most respects, pulped natural processing is similar to honey processing. Although the steps are almost identical, one of the main differences is that the Pulped Natural process was developed in Brazil to speed up the drying process, as the traditional drying process often takes a long time. Hence, it also carries many apparent risks to the quality of coffee.

Coffee is processed with yellow, red, and black honey

The term honey processing coffee often goes along with color adjectives such as coffee that processes yellow, red, or black honey.

The name “honey” has absolutely nothing to do with the taste of coffee. The reason is that during semi-wet processing, the fruit meat around the seeds is not 100% decomposed. There is always a part of sugar mucus and enzymes after natural fermentation.

If the coffee beans are dried quickly, then there will be yellow. On the contrary, the longer the moisture backlog, the coloring reactions will darken the coffee beans to red or black.

It seems that to make things more complicated, it appears that Central American coffee producers have standardized the honey processing process with color (and taste differences) based on the amount of mucus retained and the drying time:

- Yellow Honey: Coffee is removed most of the mucus (only about 25% between) by mechanical equipment, then brewed and dried quickly for 8 to 10 days. After drying, the mucus layer will close with a characteristic yellow color – like honey. The flavor is now nearly comparable to that of wet-processed coffee, and acidity can be increased depending on the coffee type.

- Red Honey: Similar to the above, but about 50 to 75% (relatively more) mucus is retained for the drying process when producing red honey coffee. The drying process is covered, creating shade for 12 to 15 days so that the grain mass dries more slowly with frequent mixing.

- Black Honey: Processing black honey is dried with almost 100% mucus. Due to the high stickiness of the coffee bean block after rubbing the shell, the coffee must be rotated and mixed regularly to avoid sticking into blocks. This is the most challenging process, requiring time and effort. It takes about 30 days to dry the coffee altogether.

Finally, we can significantly amplify their intensity and sensory properties by applying semi-wet processing on specialty coffee varieties. Coffee made from Geisha, Bourbon, Catuaı, Typica, Maragogype often scores highest in competitions such as Cup of Excellence, Specialty Coffee or Best of Panama.

However, the flip side of honey processing is that it requires careful drying monitoring. Coffee beans need to be constantly raved during drying to prevent mold growth that causes damage due to high humidity.

Reference source

- How to Make Coffee – The Science Behind the Bean by Lany Kingston ; Published in 2015 by Abrams Image

- The Craft and Science of Coffee Book by Britta Folmer, Publisher: Academic Press, 2016 | Chapter 3 Postharvest ProcessingdRevealing the Green Bean

- www.perfectdailygrind.com/ Honey processing: everything you need to know