Effect of Humidity on Coffee Roasting: Moisture is one of the most important physical properties of green coffee beans, considered a key quality parameter for coffee at all stages of the supply chain, from producer, purchasing, to the roaster. For producers and traders, moisture is considered a measure of the quality of coffee because it affects the shelf life and value of coffee beans. If the coffee is too moist (e.g. higher than 12.5%) their quality will deteriorate much faster. On the other hand, drying coffee more than is necessary for storage is also detrimental to producers and traders because for large quantities of coffee, a one percent moisture difference can have a large impact on finance.

Roasters – near the bottom of the supply chain, have two mandates when it comes to moisture management. On the one hand, they must maintain the shipments they store within the acceptable humidity range for quality standards. On the other hand – within a period of only a few minutes, the roaster is responsible for removing almost all of the moisture from the beans through high heat and pressure. During these minutes, coffee receives (a greater amount) of energy than any other time it experiences in the supply chain; The success or failure of the roasting process depends on the dehumidification mechanism and the moisture content that each bean stores.

It’s easy to see why roasters should care about the moisture content of their coffee. But how useful the manufacturer-provided numbers are, and the role of humidity in the actual variations of coffee during roasting, remains unclear. This article was made to provide a new approach to the role and physico-chemical effects of moisture in the roasting process, to make essential predictions that can be considered in the roasting process. get high.

Moisture meters

The international standard method for measuring the moisture content of green coffee is drying. This method is time consuming but should be used as an accurate reference for the calibration of other rapid measuring instruments ( ISO, 2012 ). The principle is very simple:

- Weigh a sample of green coffee, about 10 grams.

- Place in oven at 105°C for 16 hours.

- Weigh the sample a second time.

This method assumes that the difference in mass after drying is solely due to water loss, although some mass may be lost due to the decomposition of other compounds in the coffee.

However, the most common tool for estimating the moisture content of green coffee in roasters is a capacitance meter – simply called a moisture meter. As a general rule, the machine will measure the amount of charge that can build up in a layer of coffee held between two metal plates. The amount of charge that the coffee layer can hold depends on both the moisture content and the density of the coffee. For this reason, it is very important to fill the measuring chamber so that the meter can read the density accurately.

Another important note is that you must make sure the meter temperature and the coffee temperature are the same – the coffee and the sensor inside the meter both need to be at the same temperature for you to get accurate results. Therefore, the most useful advice is to leave the sample inside the meter for a while to allow the temperature of the sample and the sensor to equalize before you take a measurement.

Thus, in the scope of this article, we use the concept of moisture to refer to the amount of water that coffee beans have – very simple. However, this is a relative concept – because water does not always exist independently of the other chemical components in coffee beans! Please keep this in mind when we refer to the concept of “ water activity ” somewhere in the article.

Each seed has a different moisture content

The moisture content of coffee decreases during roasting – but even with a deep roast, a certain amount of moisture remains in the beans after roasting. Roasted coffee typically has a moisture content of 1–3%, depending on the variety and roasting conditions ( Wang and Lim 2015 ). In many coffee roasting manuals, the first roasting stage, before the color of the beans begins to change, is sometimes referred to as the “drying phase” – this is misleading. , is that the coffee will be “roasted to dry” and go to another stage, but in reality the water will continue to evaporate throughout the entire roasting process. Therefore, the actual drying stage should only be used to emphasize the faster loss of moisture in the early stages of roasting ( Eggers and Pietsch 2001).), and moreover, this period varies according to roasting conditions.

In any given batch of coffee, there are slight variations in moisture content from one bean to another – and even within the same bean, different areas have different moisture content (Caporaso et al. 2018 ) . . Then, each bean with a different moisture content will change in different ways during the roasting process.

(a) image of a coffee hat at a spectral range; (b) reconstructed image showing the predicted moisture content of the grain – on the flat side; (c) the predicted moisture content obtained at the back of the hat – the convex side; (d) the coffee sample is split into a portion placed in humid conditions (upper half) partly dried in an oven (lower half). The numbers represent the average predicted humidity expressed as a percentage (%).

The moisture content in coffee varies by bean type and even within a single bean. If coffee beans have a higher moisture content at the beginning of roasting, they tend to lose moisture more quickly at the beginning of the roasting process. At the end of the roasting process, the moisture content of all of them will equalize with the grain with the lowest moisture content. The higher airflow in the roaster also increases the rate of moisture loss from the seeds ( Eggers and Pietsch 2001 ). However, according to Scott Rao, author of The Coffee Roaster’s Companion (2014), this difference is only significant between different types of roasters – for example, air roasters (fluidized bed roasters) and drum roaster. Small changes in the airflow settings on the drum roaster have a negligible effect on the rate of moisture loss and final moisture.

Not all water boils at 100°C

The most important effect of moisture is when it leaves the coffee beans as water vapor. When roasting coffee, the first type of moisture to evaporate is the “free” water in the beans. Free water is not bound to anything inside the particle and is therefore available to participate in chemical reactions – the amount of free water is what water activity measurement tells us .

During roasting, steam builds up faster than it exits the beans and so the pressure inside the beans begins to increase. At higher pressures, the boiling point of water rises above 100°C; For this reason, the water in the espresso machine’s boiler can reach 120°C or more. As the grain temperature increases, the pressure inside the grain increases, which prevents some of the free water from evaporating. Thus, the free water continues to convert to water vapor inside the grain at temperatures above 100°C. This pressure causes the grain structure to expand, eventually causing the first crack, and also accelerates some of the chemical reactions that take place during roasting.

In addition to free water, coffee beans also contain “bound” water – water molecules that are tightly bound to the grain structure. The bound water requires more energy to evaporate than the free water. As the particle temperature increases, the bound water molecules separate from the grain structure and join the “free water pool”. This means that, for any coffee, the water activity will be higher at higher temperatures.

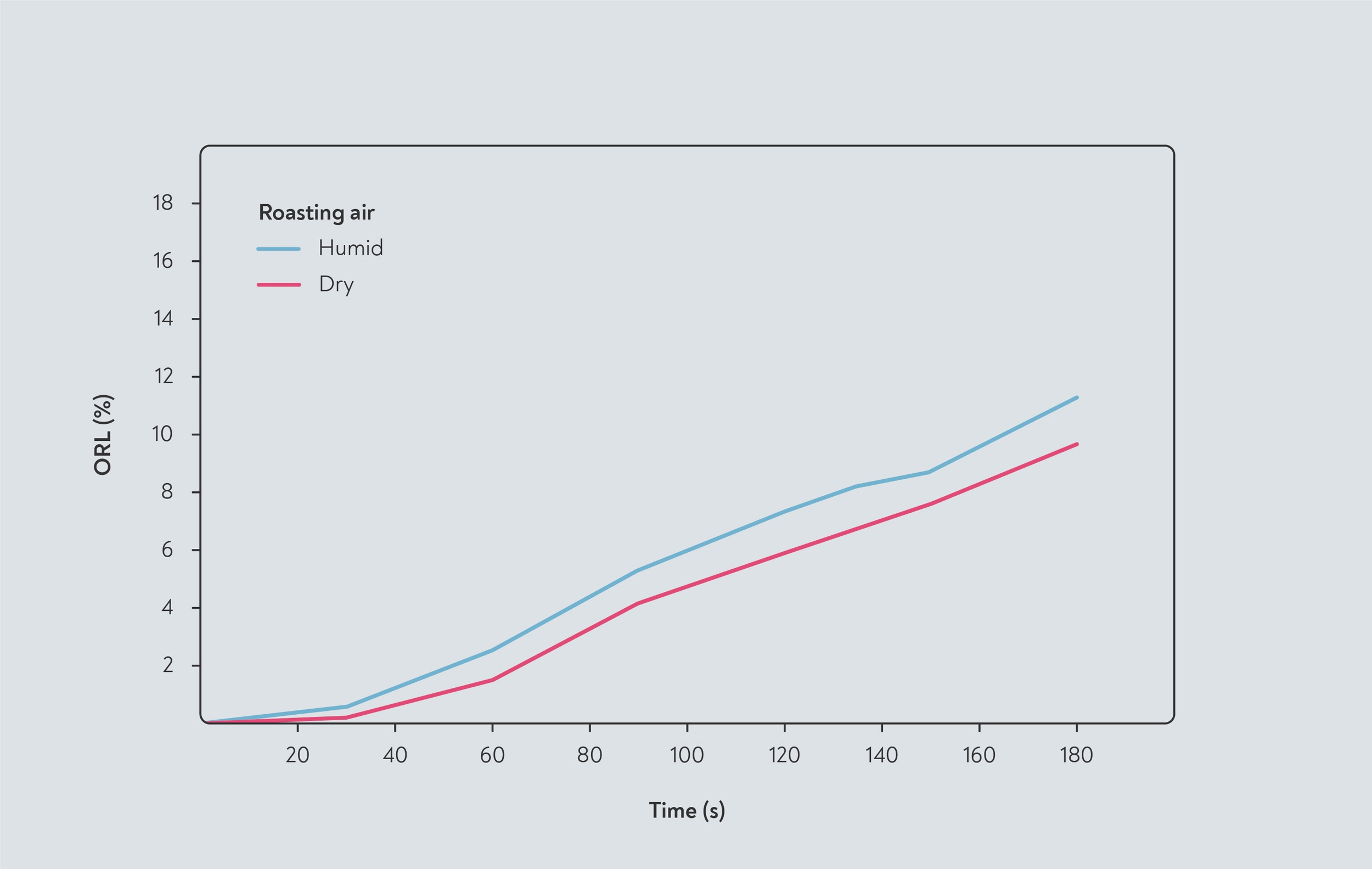

The humidity of the air inside the roaster also affects the rate of heat transfer. Moist air has a higher specific heat than dry air. The (relative) higher specific heat of humid air means that at the same temperature it carries more energy. As a result, moist air can transfer heat energy to the coffee beans more efficiently. If the air inside the roaster is more humid, roasting happens a little faster ( Schenker 2000 ).

Hot air circulation roasters usually have a more humid environment inside the roasting chamber than other roasters, and therefore the heat transfer efficiency is also higher.

Effect of humidity on heat transfer rate

The higher the moisture content of green coffee, the better its ability to conduct heat. This helps heat transfer from the surface of the bean to the center of the bean early in the roasting process, before the moisture evaporates. On the other hand, coffee with a higher moisture content also has a higher specific heat – which means more energy is needed to raise the temperature of the beans by a certain amount. Therefore, coffee with a high moisture content both allows – and requires the use of more heat in the early stages of roasting.

At the beginning of roasting, the grain temperature rises fastest near the surface of the bean, and the heat transfers more slowly to the inner layers. Therefore, the moisture near the grain surface evaporates first, creating a layer of water vapor on the outer part of the grain. This is called “evaporation front”. The evaporation front begins at the grain surface and gradually moves inward as the temperature inside the grain increases.

In the above illustration, blue is the area with the lowest temperature; Red is the area with the highest temperature. In the outer layer of the grain (1), the grain structure is expanded, more porous, and the moisture content is low, so it does not conduct heat effectively to the inner layers (2). Meanwhile, the center of the grain (3) is denser and has a higher moisture content than the surface layer, conducting heat more efficiently than the surface, so the center of the grain has a lower temperature and is more uniform. As a result, the beans will dry from the outside to the inside, while the center still contains a lot of moisture. This makes the temperature difference between the outside and the center of the grain very large. As roasting continues, this state leads to two consequences.

Corollary 1: Heat absorption barrier

Moisture near the seed surface will evaporate first, creating a layer of water vapor on the outside of the seed. The surface thus continuously evaporating will prevent the temperature from reaching deeper into the grain. As the surface layer loses moisture, it also becomes less efficient at conducting heat into the grain center.

This means that at the front of the bean, where “surface evaporation” takes place, most of the energy absorbed by the coffee bean will evaporate the water, rather than raise the temperature. Therefore, when the outer layer swells due to “water deflation”. The grain structure expands and becomes more porous, the less efficient it becomes at conducting heat, because the pores act as an insulator. Combining these two effects, when the outer layer is dry, wicks moisture, and conducts heat poorly, a temperature difference begins to form. With the grain surface at its hottest and cooling towards the center. The core of the grain, where the structure is still moist and dense, conducts heat more efficiently.

The different expansion rates of the outer and inner layers of the grain exert pressure on the grain structure, and often – as we all know, the grain breaks at its weakest points (usually the two ends of the grain).

Corollary 2: The first crack

The evaporator front has another important effect. As the temperature of the bead increases, at some point, the material of the bead undergoes a transition from a rubbery state to a brittle state – known as a glass transition . The temperature at which this happens depends on the amount of moisture – if more moisture is present, the glass transition occurs at a lower temperature.

As the roasting process progresses to a certain temperature range, the core of the coffee bean undergoes a glass transition as it gains more moisture, becomes pliable and can expand as the steam pressure increases. . On the other hand, the outer layer of the seed remains brittle because it is dried and therefore resists that expansion. As the temperature of the grain increases, stress (as the force is called from within the grain) increases as the inner region tries to inflate but is blocked by the more brittle outer layer. This stress is partly responsible for the first crack ( Fadai et al 2019 ).

During the roasting process, steam increases the pressure inside the beans (up to 25 bar*), which causes the structure of the beans to expand. When the cellulose walls of the coffee bean cells cannot stretch any further, cracks form inside the beans and on their surface, forcefully expelling water vapors and gases, creating popping noises. what we call the ” first crack ” or the first crack.

(*) This parameter is mentioned by two authors Andrea Illy and Rinantonio Viani through the famous book – Espresso Coffee: The Science of Quality (2005) but not well proven. In the current technological landscape, the researchers used several mathematical models to estimate that the pressure at the center of the grain could reach 18 bar just before the first crack ( Fadai 2018 ).

Effect of humidity on chemical reactions

In addition to affecting heat transfer, moisture also plays a role in the chemical reactions that take place during roasting. The water content and water activity at different stages of the roasting process strongly influence the rate of chemical and physical change in coffee. Water is an essential part of some reactions, such as the Maillard reaction. Other reactions (such as caramel) may not use water directly, but moisture can affect how quickly they take place.

However, while we can estimate the importance of moisture to chemical reactions – in theory, in practice it is difficult to determine how this affects the way coffee is roasted. get high. Although it is difficult to separate the role of water in chemical reactions from its effect on heat transfer, some roasters argue that higher moisture content in green coffee often leads to a higher flavor profile. better roasted coffee.

While some researchers found that adding water to green coffee (the movement to steam the coffee before roasting – to add moisture to the coffee, recently in Vietnam) improved the taste, It is also difficult to determine whether this effect is due to changes in the chemistry of the roasting process (and if so, by how much?), or just the result of differences in heat transfer. In general, however, some researchers have emphasized that “Coffee with a higher moisture content tends to have a more prominent, richer cupping flavor” (Christopher Feran 2021 ) .

Moisture generated during roasting

Certain chemical reactions during roasting create extra water, making it more difficult to fully understand the role moisture plays in roasting. These reactions can contribute up to 40% of the water released from the beans during roasting ( Geiger et al 2005 ). Therefore, even the driest green coffee beans still have some water available to participate in the reactions after the roasting process is conducted.

In the early stages of the roasting process, most of the water that evaporates from the beans is already moisture. Once this free water has evaporated, the water produced in the chemical reactions accounts for most of the moisture escaping from the coffee beans.

The amount of water that evaporates from the chemical reactions decreases towards the end of the roasting process. This could be because the compounds that fuel the reactions are running out, or because water is being used up for other reactions instead of evaporating, the researchers suggest.

Humidity and Maillard Reaction

The water content strongly influences the Maillard reaction rate. A certain amount of moisture is required in the coffee for the Maillard reaction to take place. In most foods, the Maillard reaction is fastest when the water activity ** is between 0.65 and 0.75, and most of the reaction stops when the water activity drops below 0.3 ( Wong et al. 2015 ).

(**) Note that the relationship between water activity and moisture content varies with temperature, so the water activity during roasting is not the same as the water activity measured at room temperature. For coffee with a certain moisture content, the higher the temperature, the higher the water activity ( Collazos-Escobar et al. 2020 ), so during the roasting process, the coffee, despite being significantly dry, still has sufficient water activity. high for the Maillard reaction to take place.

Since the Maillard reactions depend on the presence of a certain amount of moisture, they begin to slow down later in the roasting process as the moisture content decreases. In addition, humidity can also change the aroma mixture that Maillard reactions produce, when amino acids and carbohydrates are heated together in the laboratory ( Hofmann and Schieberle 1998 ). However, whether this effect is significant in coffee under typical roasting conditions remains uncertain.

Finally, moisture is thought to also affect the rate of other reactions in the grain. For example, moisture is involved in the breakdown of chlorogenic acid – especially in the early stages of roasting. Many reactions take place faster at higher pressures ( Clifford 1985 ). High pressure builds up inside the coffee beans during roasting due to evaporating moisture, so moisture can also affect the rate of these reactions ( Farah 2020 ).

Effect of Humidity on Coffee Roasting: Note about water activity

Water activity ( symbol a w ) is the “free” or “unchemically bound” water content of a product. In technical terms, water activity is the ratio of the partial vapor pressure of water in a substance to the partial vapor pressure of pure water (a w = p/p*; where p is the vapor pressure . of the product; p* is the vapor pressure of pure water under the same conditions). Under standard conditions, the vapor pressure of pure water is always = 1, so the water activity of a product is always ≤ 1. Green coffee, when dried to a moisture content of 10-12%, usually has water activity. in the range of 0.45 – 0.55.

- Both water activity and humidity affect the quality and storage capacity of green coffee and the risk of microbial growth during storage. Usually, the higher a w , the easier it is for microorganisms to grow. Most bacteria require a w ≥ 0.91 to grow, fungi need a w ≥ 0.7, when a w < 0.60, microorganisms are almost impossible to grow.

- The Specialty Coffee Association (SCA) requires that the water activity of Specialty Coffee be <0.7, with a moisture content of 10-12.5%.

- Also, since it is relatively easy to determine the moisture content in a batch of coffee beans (it takes only a few seconds with a hygrometer), each measurement of water activity takes between 5 and 20 minutes – even more. longer (with more sophisticated measuring equipment). Therefore, the correlation between water activity and coffee roasting is still relatively incomplete and unclear.

Reference:

-

Ảnh hưởng của độ ẩm đối với quá trình rang cà phê: https://primecoffea.com/anh-huong-cua-do-am-doi-voi-qua-trinh-rang-ca-phe

-

Coffee: Recent Developments: https://www.wiley.com/en-us/Coffee%3A+Recent+Developments-p-9780632055531