What is Anaerobic Processing?

As long as there is sunlight or a static oven, practically anyone may use the natural technique of drying coffee leaves. However, this approach is partially disregarded because the coffee is picked without a distinct classification, green, and mingled with seeds in the ripe red fruit.

Because the drying procedure is dependent on the sun or drying until the coffee dries to 12% moisture, most of the coffee’s characteristic pleasant smells are not disclosed. Because the wet processing method (semi wash) or honey processing is more successful, this method is gradually being phased out.

However, in recent years, the method of drying natural coffee berries has significantly been adjusted to preserve the value of the original coffee beans while also pushing the coffee aroma to a greater level, boosting the taste of the coffee beans. The cool fermentation anaerobic approach – drying and cold brewing – must be highlighted for the sweetness of coffee beans.

The coffee is harvested red, cleaned, and picked up the unqualified berries before being washed and hung to dry. This drying method uses natural sunlight and wind to ensure that the coffee dries slowly and the amino acid nutrients and the sugar content soak into the green core (This method of preliminarily processing coffee is approved by coffee experts). Malaysian coffee study aims to promote the benefits of this well-known national Liberica jackfruit coffee line.

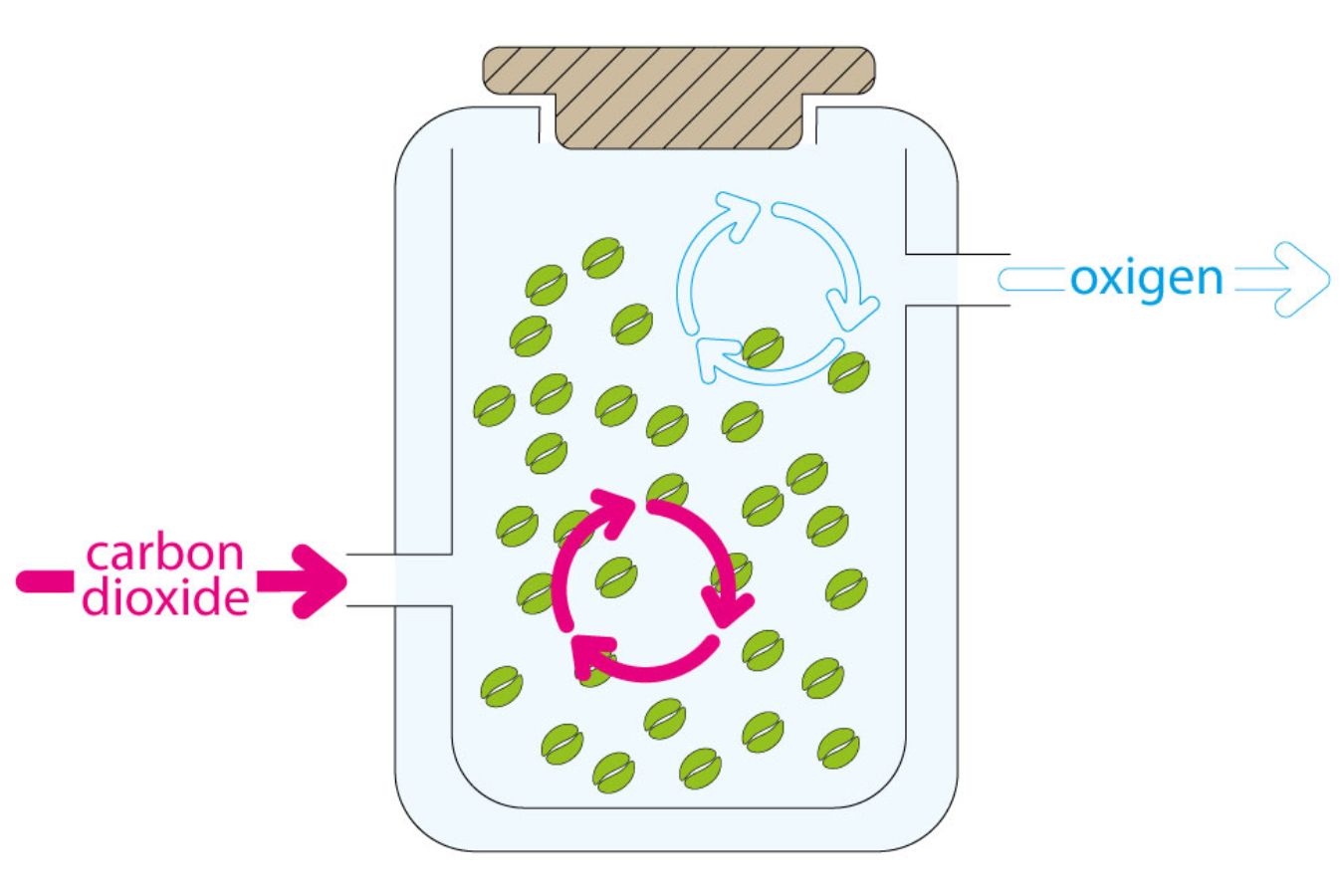

The anaerobic coffee processing method is a natural drying technique-based method of processing coffee. The coffee used in this procedure must be 100 percent red and ripe, and it is washed in a tank before being picked up and removed the rotten fruits, dried on a drying rack, and then placed in a bag. Avoid sunshine, which is usually 24 degrees, if you want to be anaerobic in a cold temperature. After the anaerobic satisfies the specifications, the machine checks the acid and sugar content of the coffee and then removes the drying net.

Drying the anaerobic coffee fruit is especially difficult since the drying temperature is controlled between 25 and 27 degrees Celsius, primarily by air drying. The coffee must be reversed regularly throughout the drying process to avoid being destroyed. When drying, the coffee should be about 12 percent moisture with a drying time of about 23-25 minutes in the sun.

The coffee is then packed and stored at a steady cool temperature for four months, after which it will be ground because the coffee flavor is so strong at this point that there is no need to roast it. Feel the coffee’s full flavor.

Helena is now using the anaerobic coffee processing technology in her coffee manufacturing. To provide customers with a unique, unadulterated experience of pure natural coffee, as well as coffee processing techniques, so that the aroma of herbs, honey, flowers, and the sweet, salty, bitter, and sour taste of coffee beans are promoted more and end-users experience the greatness of coffee, and to help eliminate the misconception that coffee must be black, thick, and foamy, as held by the vast majority of Vietnamese coffee drinkers.

When using the anaerobic method of natural fruit drying, Khe Sanh arabica coffee has a powerful aroma when it is still husked rice when it is ground, roasted, and ground, all the senses of smell sweet and sour taste of pure arabica coffee are unleashed powerfully, which helps Khe Sanh coffee compete with arabica coffee regions elsewhere.

Anaerobic digestion process

Anaerobic digestion of spent coffee grounds (3 kg m3 day1) with efficient solids recycling resulted in 99 percent solids conversion and gas yields of 054 m3 kg1 (56–63 percent methane). Gas production decreased steadily over the test period, falling from an initial value of 170 litre litre1 day1 to 045 or 033 liter litre1 day1 with or without nitrogen supplementation after 80 days. Declining gas flows were not accompanied by other typical symptoms of digester failure and were not caused by nitrogen, phosphorus, or trace metal deficiency.

Inhibited digester liquors contained an unidentified component that inhibited gas production by fresh digestion liquors. This component was not heavy metal, caffeine, or brown ‘melanoid’ pigments. Digestion liquors could not be adapted to overcome this inhibition.