Crack When Roasting Coffee – The explosive point and explosion process begins from a single sound to a series of explosive noises of the particle strengthening and then ceasing.

1. Head blast point and explosive process evenly (1st crack & full crack)

The explosive point and explosion process begins with a single sound to a series of explosive noises of the particle strengthening and then ceasing. The first explosive point describes the sound of steam and CO2 gas being squeezed from inside the center of the coffee bean. To reduce heat loss, open the airflow slightly at the commencement of the first crack to release steam and CO2.

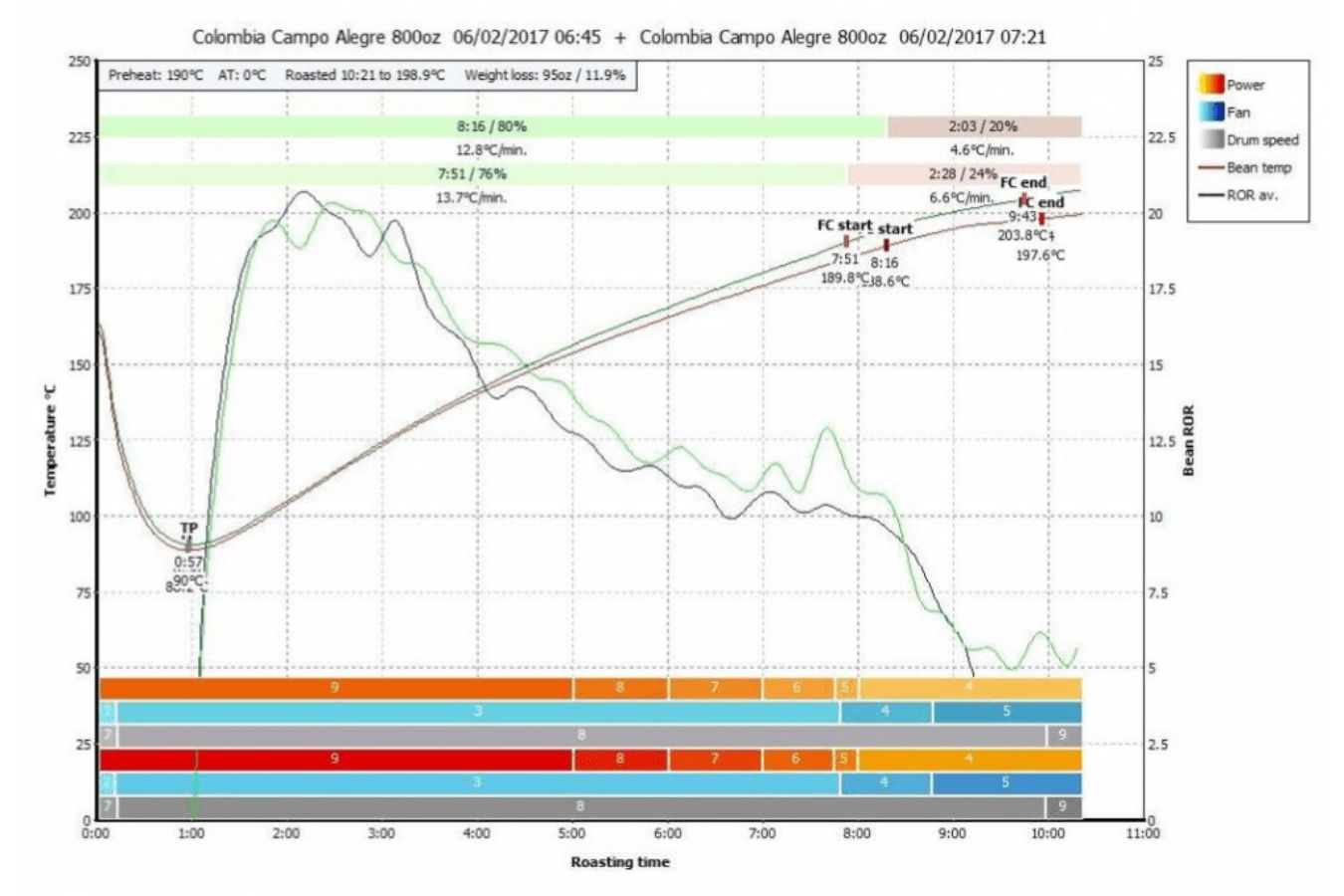

To minimize undesired heat fluctuations entering the roasting batch, the wind must be opened a few seconds after the initial explosion point (in the full crack). Arabica particles have an early explosive end at 192-198oC, but Robusta particles have an explosive issue after 200oC.

It’s worth noting that as the whole fracture opens, the airflow accelerates as a loud boom repeatedly erupts, releasing steam and CO2. This procedure typically lasts 15-45 seconds following the first crack (blast 1). The continuous explosion will occur next to the head explosion if the heating and throttle are perfect.

If the flurry occurs too late (a few minutes) after the head explosion, it is likely due to a low gas level or a heating charge that is not normal. The duration from the start of roasting to the first explosive point generally / should account for 75-80 percent of overall roasting time, equating to 20-25 percent of the seeds’ growth time.

2. Second explosive point (2nd crack)

– After the whole 1st crack has been completed, the coffee beans will be “resting” for a brief time while C02 gas is created in the grain’s core. This pressure can push oil from inside the particle to the particle’s surface (because the thermolysis process and the “wound” of the head explosion have weakened the cellulose structure of the nucleus).

– The two explosions start when oil emerges on the particle’s surface, and the explosion also releases CO2 and grease from inside the particle.

– The sugar reaction and warming of the stool for too long can damage many of the qualities of the coffee beans when they are roasted to the point of bursting two.

– The seeds begin to oxidize extensively when the roast reaches the level of explosion 2.

Total Time development

– From the beginning explosive point until the end of the roasting process, the stage of development is frequently calculated (pouring the seeds out of the empty cage to perform the cooling process on Cooling Tray).

– If the time-dev time is less than 20% of the total roast time, the seeds have not grown enough, and the coffee will have a brief and imbalanced aftertaste. The more quinic and caffeic acid increases the bitterness of the aftertaste, the longer the roasted batch, the time-dev time of 25%.

– The color of the coffee beans and the degree of roasting will be determined at this step. At the time, the balance between the sour and bitter tastes of the coffee beans was chosen based on the purpose of usage and “taste” (gout). As the roasting process progresses, the sour flavor will fade swiftly, but the bitterness will drastically rise.

Air-flow

There are also instructions for leveling and closing the airflow during roasting in other products. However, since this is a crucial aspect in determining the roast batch’s quality, the following information is synthesized once more:

– When the machine is first started, and the roast drum is heated, the wind is often closed entirely to prevent heat and fuel loss.

– Count on the machine’s innovative Airflow design structure to set the wind level to a low level at the start of roasting and modify it suitably during the roasting process.

– Do not control wind (or gas) at key phases like the point of transfer or the endpoint of crucial reactions like the Maillard Reaction, Strecker Degradation, Lipid Oxidation, Caramelization, etc. To prevent quick heat loss and roasting particle failure, do not open the wind soon before or after explosion 1.

– When beginning into the full crack, however, it is vital to open the high wind to swiftly escape the CO2 and steam created to prevent the roasting batch from developing a defective flavor (smokey taste, impurities,…)

As the roasting progresses, the wind is advised to be opened completely to ensure that the particle produces the least amount of hazardous gases and pollutants from its processes.

Bottom Line: During roasting, controlling ventilation is critical since it impacts the length of time the temperature affects the beans. Probate, for example, features a three-step installation technique for ventilation openings (fully automatic, inconsequential).

Because the machine is supposed to be entirely closed, Probat includes a mode: always open 20- 25 percent /32 percent (before 1st crack)/55 percent: to produce convection airflow in the coffee block (dust, steam, coffee eyebrows, air). Exchanging air and moisture straight from the outside environment into the roasting cage is what opening ventilation entails. As a result, ventilation monitoring will include heat loss/heat exchange during roasting.