Illustrated Diagram Of Coffee Processing Methods? Helena coffee helps you learn about coffee processing methods.

Some terms to consider:

1. The phrases “sometimes” (yellow) and “rarely” (red) are both relative terms.

For example, baking coffee berries in water after picking to reduce cherry float is an optional but frequent step in Washed early processing. Even with natural coffee, farmers worried about the quality are increasingly soaking the berries. (The MIMOSA coffee from 96B is steeped in water to remove the green and light fruit.)

2. Fermentation/softening process used in the past: The fermentation technique for softening (maceration) the mucilage in coffee berries is not new, as previously discussed. Fermentation is a natural process that has been utilized in coffee processing for a long time.

3. Softening/fermentation in airtight tanks: Only the fermentation process, such as developing a specific medium or inoculating yeast/bacteria, should emphasize the coffee producer. This method can be used to create different coffee flavors.

4. Washing in the washing channel: Common in washing stations with adequate facilities in the Americas, as well as in several African countries, including Kenya, Burundi, and Rwanda.

5. Coffee processing is becoming increasingly complex and diverse:

Don’t use an overly rigid flowchart. Although MIMOSA of 96B is labeled as SC natural, we use the ‘Cherry flotation’ and ‘Fermentation’ steps (fermentation in water). Similarly, many Carbonic maceration coffees are hulled before fermentation and hence do not ferment the entire fruit.

6. This approach excludes procedures that are too new and unpopular, such as skin contact (soaked with peeled coffee beans). Some ‘traditional’ methods are also left out, such as the Indian Monsoon Malabar. (I regard monsoon to be a preprocessing stage because it directly impacts the flavor and brand of coffee.)

Popular Coffee Processing Methods

Structure of the Coffee Fruit

7. Crust: this is the outermost layer of the coffee. The colour changes during growth, green when the cherries are still green, and red when the cherries are ripe or yellow (yellow bourbon).

6. Fruit flesh: this is the next part of the peel, sweet and full of edible sugars that make up 42-45% of the weight of ripe coffee fruit.

5. The viscous layer: is an essential component of the ripe coffee fruit. It accounts for 20-23% of the weight of the ripe coffee fruit and is responsible for protecting the kernel from insects when the coffee has not been picked. An essential ingredient in honey-making, but often fermented and washed in wet processing.

4. Paddy shell: is the hard shell remaining after preliminary processing, accounting for 6-8% of the weight, and is responsible for protecting the kernel inside. This layer will be removed before being roasted to avoid burning.

3. Silk shell: silvery white surrounds the kernel. This is the flavor factor for coffee after roasting.

2. Kernel shell: is a thin shell to protect the main kernel, full of the flavor of coffee, and contains little or no caffeine.

1. Main kernel: full of nutrients, full of coffee flavor, and contains the most caffeine.

Preliminary Processing Of Green Coffee Has 3 Popular Methods

Dry processing (Natural/ Dry/ Unwashed)

Ripe coffee after being harvested, remove objects such as leaves and branches of coffee mixed in, brought to the drying yard without new milling. The coffee leaves are left to dry until the moisture is about 12-13%, and the drying time is from 20-25 days depending on the outdoor temperature.

After drying, the dried coffee cherries will be milled to remove the husk and produce green coffee beans. When processed by this method, the coffee beans will be sweeter and less sour, bringing more flavour to the cup of coffee.

Full washed/ Washed/ Wet.

This method is more complicated than dry processing and requires specialized machinery. The main feature of this method is that the skin and pulp are removed before the coffee is dried. This method results in uniform coffee quality, quality and colour, with minimal defects affecting the tasting quality.

Coffee after harvest contains many impurities such as branches, leaves, soil, worms, and green fruits, .. so preliminary processing is essential as soon as possible to ensure the quality of the harvested coffee batch. At this stage, the coffee is washed in a water processing tank and then sent to a vibrating screen to sort ripe fruit from the green fruit, and large fruit from a small fruit.

After being carefully screened, the coffee needs to be transferred to the grinder immediately to avoid affecting the quality of the beans. At this stage, the skin, fruit pulp, and viscous layer are separated, and the coffee is cleaned.

After being processed by the milling machine, the fruit pulp, the dense layer remaining on the rice husk, will be thoroughly cleaned by the fermentation process. Usually, the finished coffee is put into large buckets of water. Coffee beans are fermented by natural enzymes or can add enzyme products.

This process lasts from 24-36 hours, depending on the thickness of the dense layer and enzyme concentration. After this process, the thick layer loses its structure and is easily washed away by water.

After fermentation, coffee beans with a moisture content of 46-47% will be dried to a moisture content of 12.5%. Depending on temperature and light, this process can be done by a dryer or by drying the paddy coffee outdoors for about 8-10 days. Finally, it is carefully preserved to keep the quality of the coffee beans. This method gives coffee beans a uniform, clean, citrus sour taste and outstanding coffee quality.

Semi-wet processing (Honey)

Processing by the Honey method requires high technology. The main feature of this method is to select 100% ripe coffee for processing. The amount of sugar in the coffee fruit reaches the highest, the highest quality of freshly processed coffee.

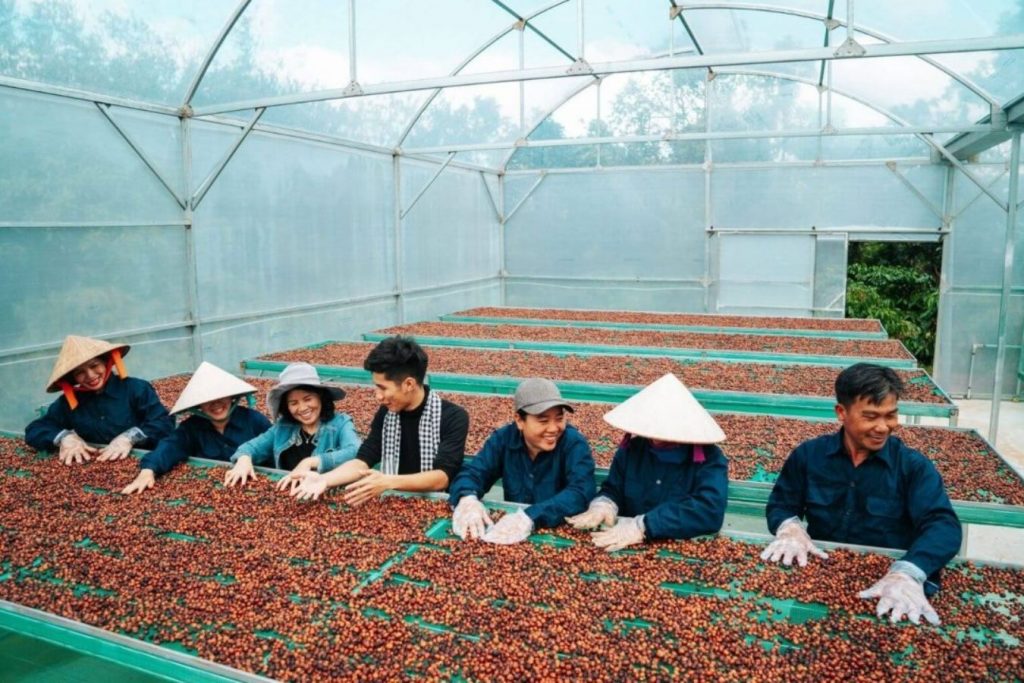

Ripe coffee is put into the grinder, and after being milled, the coffee beans still sticky with mucus are placed on the frames of the natural sun drying frame, which is a certain distance from the ground. Usually, it will be dried for about 12 days, and the moisture content of the coffee after drying is 12%.

Based on the dense layer that clings to the rice husks when drying, Honey coffee is divided into four types:

- White Honey: 10-15% of the mucus adheres to the rice husk.

- Yellow Honey: has 15-50% of mucus clinging to the rice husk.

- Red Honey: 50-90% of the mucus adheres to the rice husk.

- Black Honey: 90-100% of the mucilage adheres to the rice husks.

The Honey processing process yields coffee beans with sourness, uniformity, fullness, floral aroma, rich fruit, and sweet taste.

Ending

I hope this diagram makes the basic preprocessing methods and their variations easier to grasp and comprehend. If you wish to go deeper, each step in each approach will have its variations, and no flow chart will be able to show them all.

For instance, consider fermentation: Is it possible to be fermented with wild yeast? By the fungus Brettanomyces? Saccharomyces sp. groupings Wild yeast fermentation followed by saccharomyces fermentation? Yeast + bacteria fermented?

Fermentation at a low temperature and then gradually increasing the temperature? Is it fermented with wild yeast or farmed yeast? The producer can try out various ways with each batch of coffee.